Heat welding is an advanced plastic bumper repair method, offering precise, durable, and cost-effective solutions compared to traditional adhesives. This technique fuses components together, eliminating weak points and air pockets for enhanced structural integrity, while reducing the need for toxic chemicals and streamlining collision repair processes. Favored by car body shops, heat welding handles complex damages like cracks, dents, or full replacements, creating a strong, seamless bond that can withstand significant force. Its precision allows for intricate repairs, preserving the original shape and aesthetics of the plastic bumper, ultimately maintaining the car's appearance and resale value.

“Revolutionize your approach to plastic bumper repair with heat welding—a game-changing technique gaining traction in the automotive industry. This advanced method offers a robust solution for restoring damaged plastic bumpers, ensuring long-lasting results. Heat welding provides an efficient, cost-effective alternative to traditional methods, appealing to both professionals and DIY enthusiasts.

In this article, we’ll explore the science behind heat welding, its numerous advantages, and provide a comprehensive step-by-step guide to mastering this skill for precise plastic bumper repair.”

- Understanding Heat Welding: A Powerful Technique for Plastic Bumper Repair

- The Benefits of Heat Welding in Advanced Plastic Bumper Restoration

- Step-by-Step Process: How Heat Welding is Performed on Plastic Bumpers

Understanding Heat Welding: A Powerful Technique for Plastic Bumper Repair

Heat welding is a highly effective technique within the realm of plastic bumper repair, offering precise and durable results for auto body services. This method involves applying heat to melt and fuse two or more plastic components together, creating a strong bond that can match or even surpass the original manufacturing quality. It’s particularly useful in collision repair where replacing entire plastic bumpers can be costly and time-consuming.

Compared to traditional adhesive methods, heat welding provides several advantages for vehicle body repair. It ensures better structural integrity by eliminating air pockets and weak points often associated with adhesives, making it a reliable solution for long-lasting repairs. The process is also more environmentally friendly as it reduces the need for toxic chemicals commonly used in some adhesives. Moreover, heat welding can be more cost-effective and faster than other repair methods, contributing to streamlined collision repair processes.

The Benefits of Heat Welding in Advanced Plastic Bumper Restoration

Heat welding offers a range of benefits for advanced plastic bumper repair, making it a preferred method among car body shops and vehicle repair services. This technique is particularly advantageous when dealing with complex plastic damage, such as cracks, dents, or complete bumper replacements. By using heat to fuse broken or separated plastic parts, this process ensures a strong and durable bond, restoring the structural integrity of the bumper.

Unlike traditional gluing methods, which might not provide adequate strength for heavy-duty vehicles, heat welding creates a seamless joint that can withstand significant force. This makes it ideal for vehicle collision repair, as it guarantees long-lasting results. Moreover, the precision involved in heat welding allows for intricate repairs, preserving the original shape and aesthetics of the plastic bumper, which is crucial for maintaining the car’s overall appearance and resale value.

Step-by-Step Process: How Heat Welding is Performed on Plastic Bumpers

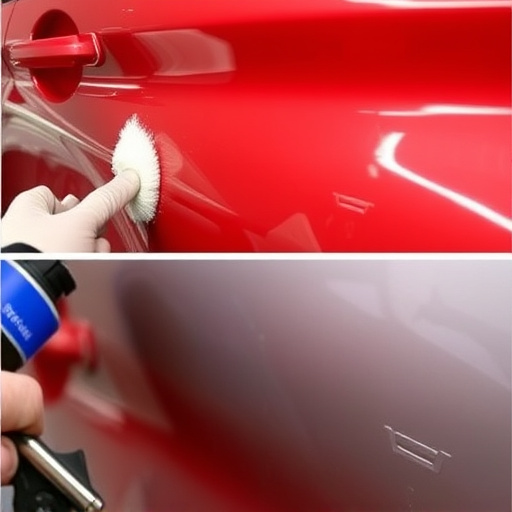

The process of heat welding for plastic bumper repair is a meticulous art that involves several precise steps. It begins with the preparation of the damaged or cracked bumper, ensuring its cleanliness and dryness to guarantee a strong bond. The broken or split parts are then carefully aligned, often requiring specialized tools to achieve a perfect fit. Once in place, a powerful heat source, usually a heated tool, is applied along the joint line. This process causes the plastic to soften and melt slightly, creating a seamless fusion between the two pieces. As the heat welding progresses, the operator ensures even heating to prevent warping or discoloration, maintaining the bumper’s original integrity.

After the heat welding is complete, the excess material is trimmed, and the entire surface is inspected for any imperfections. This meticulous repair technique not only restores the aesthetic appeal of the plastic bumper but also reinforces its structural integrity. Many collision centers and auto repair services now employ this advanced method to provide top-notch plastic bumper repair, ensuring vehicles return to their pre-incident condition.

Heat welding has emerged as a game-changer in the realm of plastic bumper repair, offering advanced restoration solutions. By utilizing this powerful technique, professionals can now achieve precise and durable repairs, enhancing the overall quality of vehicle aesthetics. The benefits are clear: faster turnaround times, reduced material waste, and superior bond strength. With its step-by-step process, heat welding ensures a meticulous approach to plastic bumper repair, making it a reliable choice for both auto body shops and dedicated restorers.